Plastic extrusions, we can provide good quality and good prices and timely delivery for you!

China Plastic Extrusion

China Plastic Extrusion Ltd.(CPE) was founded in Shenzhen China since 2007 as a manufacturer of custom plastic extrusions, CPE gain vast experience in the extrusion of complex profiles of all shapes and sizes using an impressive variety of traditional and advanced resins.

Our excellent skills in the field of plastic extrusion enable us to produce high-quality products. In addition, our attentive service and competitive prices have won the long-term trust of many customers around the world.

Next time you need a price for extruded parts, please send us an email and we will respond to any questions you may have and provide prices for your reference, regardless of whether you will purchase our products.

Our email: sales@ChinaPlasticExtrusion.com

ISO 9001:2015 Standard. Registration No.: 00922Q10077R0S.

For any query

Please fill below form

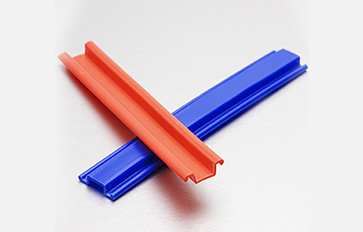

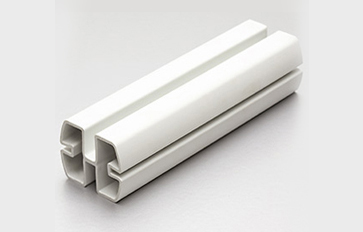

OUR PRODUCT

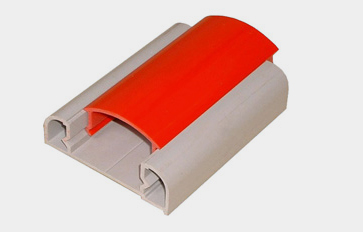

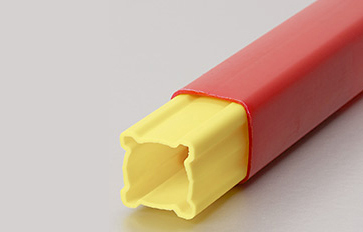

The plastic extrusion we can do including: Extruded plastic profile, Manufacture plastic extrusion profiles, Plastic Extruded Part, Extrusion mold, Insulating sheets for ORV3 RACK BUSBAR, Fluted Tube, Flip Lens, Feeder tube, PVC Corner Profiles, Ribbed Handle, Safety Rack, Signage, Frame, Interlocking Profiles, Panel Connector, Lens Cover, Vane Blade, With Reflect Tape, Interlocking Profile – Pedestal, Clear Tubing, Welded Gasket, Co-Extrude Interlocking Profile, Rail Profile, Expansion Joint, Off Center, Translucent Signage, Coping, Blade Wiper, Signage Display, Wear Strip, Kickplates, Handrail Covers, Floor Strip, Display Unit Trim, Price Channels, Magazine Racks, Baseboard Covers, Basement Wall Forms, Thresholds, Door Frames, Housing Frames, Window Trim, Footer Drains. Please note that these are not stock products. These images are to illustrate typical parts we process.

CAPABILITIES

Advanced capabilities to meet your demanding extrusion challenge

We run most common thermoplastics resins, including ABS, PC, PMMA, flexible and rigid PVC, HDPE, PP, POM, PPE(PPO), TPE, TPV, TPR. in innovative engineering resins, such as ABS/PVC alloys and difficult-to-run elastomers, such as acetal, Santoprene, nylon and glass-filled ABS. We can also combine different resins according to your needs. To keep abreast of the latest developments in plastic technology, we are always evaluating new materials so check with us when you have an unusual request. Among the many resins which we routinely extrude are:

• ABS/PC

• Alcryn

Polystyrene

• Delrin

• Polypropylene

• HDPE

• LDPE

• Polycarbonate

• Polystyrene

• PVC Alloy

• Rigid PVC

• Santoprene

• Urethane

Advanced capabilities to meet your demanding extrusion challenge

CPE’s machines’ single screw units range from 3/4″ to 2 1/2″ which allows us to extrude a wide range of sizes and shapes. We can produce profiles ranging in size from 1/16″ to 5″ pipe or 10″ profile with a virtually unlimited length. So chances are, we can do the size you need.

Advanced capabilities to meet your demanding extrusion challenge

An important part of CPE’s extrusion solutions is our full range of secondary operations, including drilling, punching, milling, sawing, printing, application of tape and sub-assembly work. Your part can be ready for you to install when you get it. This saves you time and money in your manufacturing process.

Advanced capabilities to meet your demanding extrusion challenge

At CPE, our people are not only experienced; they are conscientious – we take pride in our work. That means 100% quality checks and close tolerance operations, AQL Quality Inspection.

Advanced capabilities to meet your demanding extrusion challenge

CPE has comprehensive in-house tooling capabilities from die manufacturing to vacuum sizing, and we operate our extrusion lines 24 hours a day. All of this speeds up the turn-around time and helps get your job delivered on time every time. And we can offer you just-in-time delivery if you need it to streamline your manufacturing process.

Advanced capabilities to meet your demanding extrusion challenge

Each of our plastic extrusion engineers has at least 8 years of on-the-job experience, while our tool and die engineers has more than 7 years of experience. In fact, the average length of on-the-job experience of all our extrusion operators is over six years.

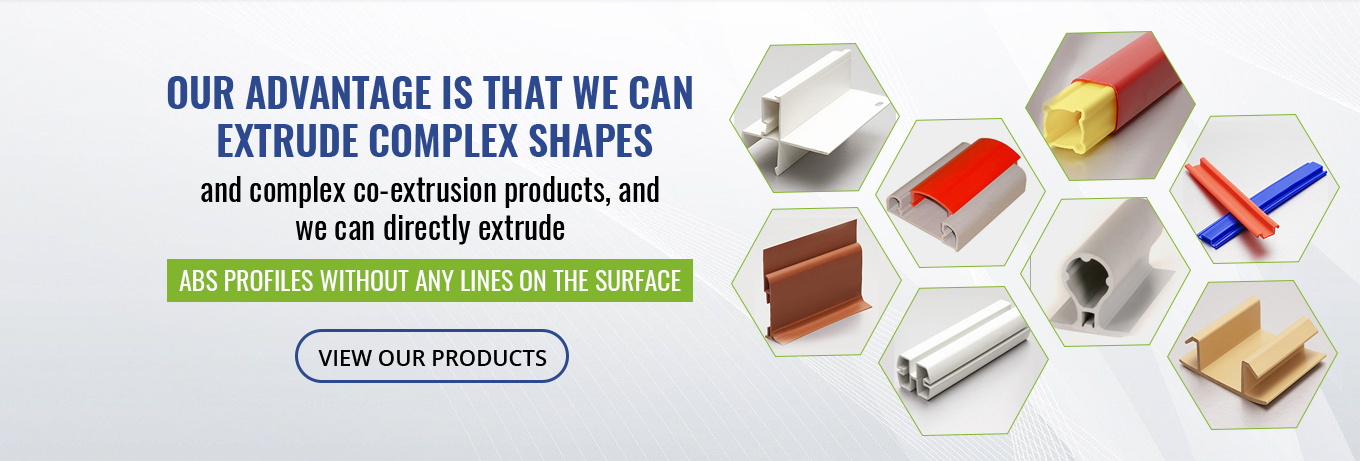

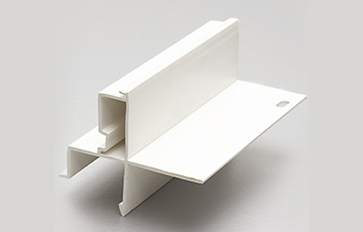

China Plastic Extrusion Ltd advantage is that we can extrude complex shapes and complex co-extrusion products, and we can directly extrude ABS PROFILES WITHOUT ANY LINES ON THE SURFACE.

CPE’s predominant area of expertise is in the manufacture of custom plastic extrusions. By teaming up with our Extruded Plastic Specialists, customers have the opportunity to improve their effectiveness and performance in their manufacturing. We design our tooling in-house. Our engineering staffs are familiar with most thermoplastic extrusion-grade materials. We can help our customers choose the best material for their extruded plastic application. We can produce custom colors that are matched to customer’s specific needs and requirements. Our value-added secondary operations, such as notching, punching, drilling, cutting, welding, printing, and Labeling & UPC Application.