A Quick Overview Of Plastic Extruder

A plastic extruder is a type of machine that melts and shapes raw plastic pellets or flakes into channels, tubes, sheets, or other shapes. Plastic extruders are machines that use the physics of friction and pressure to partially melt or plasticize, raw plastic material, squeezing the molten material through a shaping die at the outputting end.

During the extrusion process, gravity feeds plastic pellets or flakes through a hopper down into the extruder’s enclosed screw conveyor channel. This conveyor moves the raw plastic along toward the other end, shearing and heating the plastic; electric heaters built into the conveyor often aid the melting process. The molten plastic is made into a selected profile because it is pushed, or extruded, by the die at the open end.

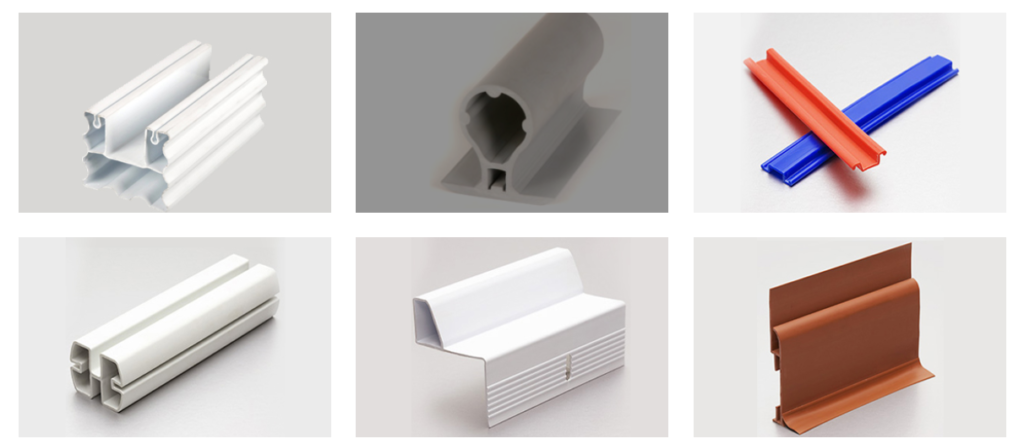

The newly formed plastic profile is instantly cooled with cold water, pulled through by a series of conveyors, and move appropriate lengths. Extruded plastics manufacturers use plastic extruders to form plastic profiles, plastic channels, plastic rods, plastic tubing, and plastic sheets, all of which play an important role in virtually every industry, from the buyer products manufacturing industry to the medical device development industry.

Plastic channels and profiles are often manufactured continuously and are utilized in window profiles, building siding and trim, gutters and channels, sealing sections, hoses, curtain rods, tubes, pipes, drinking straws, and lots of other common products.

Extruded plastic sheets are utilized in packaging and are often thermoformed into consumer products and packaging. Plastic rods and thick gauge sheets are machined by automotive, aerospace, and construction industries into parts for close tolerance applications.

The extrusion process is very customizable and is capable of high volume production also as short runs, making plastic extrusion one among the foremost diverse and economical methods of plastic fabrication. The plastic extruder can extrude any thermoplastic material (that is, plastic material that changes its form under various levels of heat), including HDPE, LDPE, PETG, PVC, butyrate, vinyl, polypropylene, and polystyrene.

The plastic extrusion process is liable for the assembly of everyday necessities like PVC pipes, indoor and outdoor window trim, sealing bars, siding, plastic gutters, plastic sheeting, toys, recreational accessories, and far more. Since the extrusion process uses the endless output of smooth, thoroughly heated, and mixed material, extruded plastics seldom have bubbles or inconsistencies, and that they are therefore valued for his or her structural integrity and consistent, precise profiles.